xiamen ZONEWU The LoRaWAN Oxygen (O2) Sensor is a wireless gas monitoring device developed using LoRa wireless technology. It is equipped with a high-performance oxygen sensor and a temperature and humidity sensor, which can measure the oxygen concentration, temperature, and humidity in the environment in real time. This sensor detects accurately, has stable performance, and is especially energy-efficient. It supports the standard LoRaWAN protocol and can transmit data over long distances.

Produktmodell :

LW305-O2Stromversorgungsmodus :

Battery or External DCFrequenz :

CN470/IN865/EU868/RU864/US915/AU915/ KR920/AS923-1&2&3&4MAC-Version :

LoRaWAN 1.0.3Modus :

OTAA Class A/CGewicht :

120gEnvironmental LoRaWAN Oxygen (O2) Sensor

xiamen ZoneWu LoRaWAN Oxygen (O2) Sensor is a new type of wireless Internet of Things gas monitoring device that can collect, monitor and transmit data.

xiamen ZoneWu LoRaWAN Gas Sensor O2 Sensor Features:

It can monitor the oxygen concentration in the environment in real time, as well as measure temperature and humidity, and collect these data.

A three-electrode electrochemical gas sensor was used to measure oxygen specifically, with a high-performance microprocessor to process the data, and a temperature and humidity sensor was also built-in.

Performance advantages:

It supports the LoRaWAN protocol and can transmit data wirelessly over a long distance.

It can be used in industrial production, agriculture, underground pipelines, and other places where oxygen needs to be monitored.

The collection, monitoring, and transmission functions are integrated together, and the remote monitoring is realized by wireless technology, which is suitable for various scenarios.

Technical Parameters

| Power Supply | 5~28VDC |

| Weight | 120g |

| Operating Temperature | -20℃~50℃ |

| Measuring Principle | Electrochemistry |

| Lifespan | <2 years |

| Measuring Range |

02 (0-25) %VOL

Temp:-40~+80 ℃

Humi:0~99.9 %RH

|

| Frequency |

CN470/IN865/EU868/RU864/US915/AU915/

KR920/AS923-1&2&3&4

|

| Mode | OTAA Class A/C(Default: Class C) |

| Reporting cycle |

External power supply:5min(Default reporting cycle)

Report after preheating for 3 minutes when powered on

|

| Communication Protocol | LoRaWAN,LoRa TDMA Networking |

|

Equipment information

(Reference)

|

LoRaWAN,LoRa TDMA Networking

AppEUI:0000000000000001

DevEUI:aaaa202404150001

AppKey:00001111222233334444555566667777

MAC Version:LoRaWAN 1.0.3

|

Product Applications

1. Accurate measurement data: the sensor surface has a layer of particularly sensitive film, which can immediately sense oxygen changes as soon as it is touched. The microprocessor inside will analyze the data in detail and give accurate values in real time with minimal error.

2. Low power consumption: Using advanced low-power technology, the sensor can work for a long time without consuming electricity, which not only extends the use time but also saves maintenance costs.

3. Durable and stable: the material and process are very meticulous, even if the environmental temperature and humidity are extremely extreme, the performance will not change, and the measured data will always be accurate.

4. Fast response: Sensitive to changes in oxygen concentration, can respond quickly, suitable for places that need real-time monitoring.

5. Can transmit data wirelessly: supports LoRa wireless transmission, can report data over a long distance.

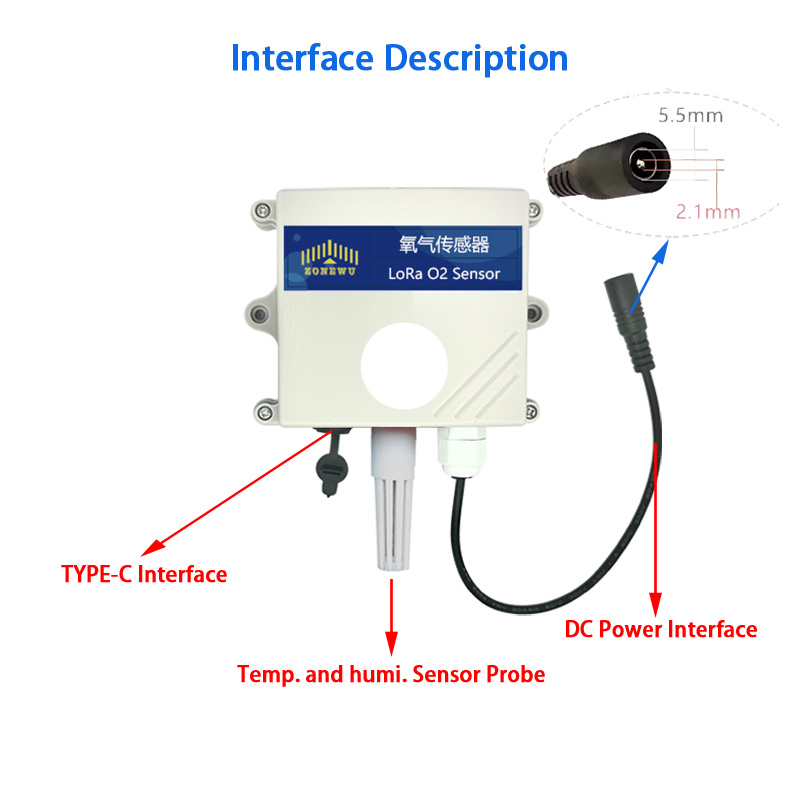

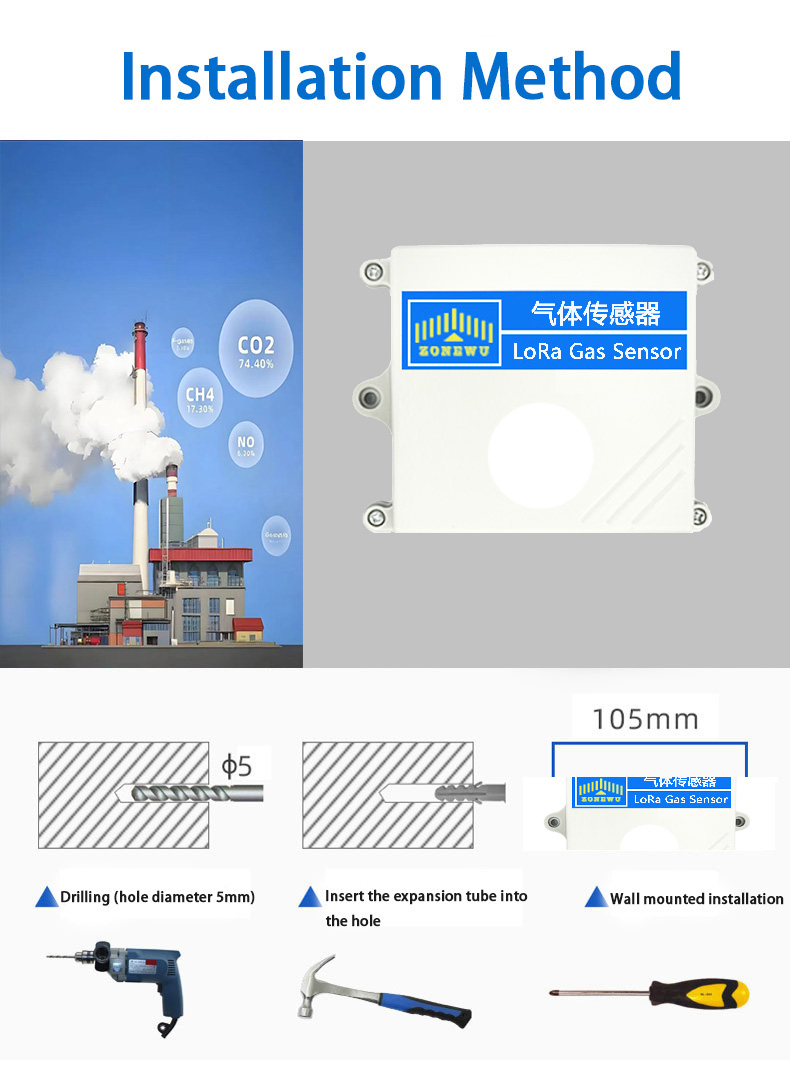

Detailed Images

Common knowledge of O2

What is the use of oxygen sensor

It is used for real-time monitoring of oxygen concentration in the environment, ensuring production safety (such as preventing hypoxia or hyperoxia risks), and ensuring the normal operation of equipment (such as monitoring the combustion efficiency of engines).

What are the common types of oxygen sensors

There are mainly three types: electrochemical type (suitable for low concentration monitoring), zirconia type (suitable for high temperature environment), and paramagnetic type (commonly used in high precision industrial scenarios).

How to maintain the oxygen sensor

Regularly clean the sensor surface impurities, avoid contact with corrosive gases, calibrate the data according to the instructions, and replace the aging or failed sensor in a timely manner.

Application Scenarios

Industrial production

Waste gas emission monitoring: Conduct real-time monitoring of industrial waste gas emissions to ensure that waste gases meet emission standards and reduce pollution to the environment.

Environmental inspection

Air quality monitoring helps people understand air quality and protect the environment and health by detecting harmful gases such as sulfur dioxide.

Safety protection

In coal mines and tunnels, gas sensors detect toxic and harmful gases such as methane and warn against accidents.

A:Yes,we can provide you with OEM services and design housings and logos.

3.DO you offer free samples?

A:Sorry,we don't offer free samples. After ordering in bulk, we will deduct the sample fee from the second order.

Why Choose ZONEWU